Everyone has bought products packaged in plastic, either bagged or heat sealed. So much food is presented this way in the supermarket. But how is the food sealed in those bags and kept fresh?

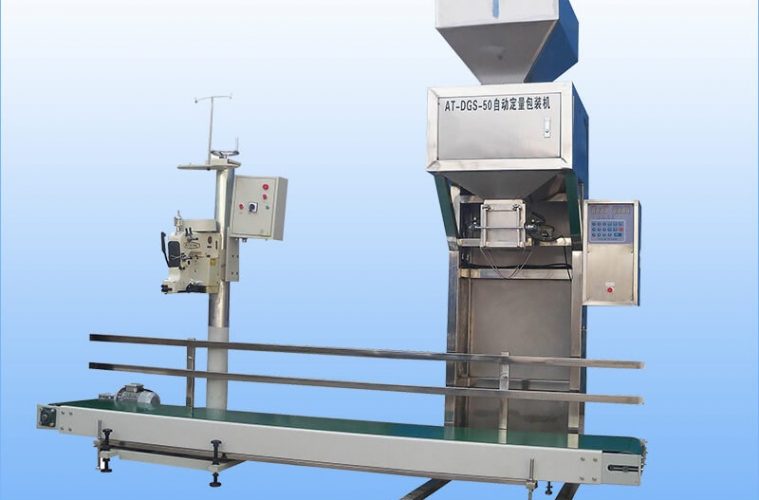

A

bag sealing machine

is a very helpful addition, or essential, to any production line that involves end products in hermetically sealed bags. It efficiently and methodically seals each product at the end of the preparation line.

Sealing machines may work though heat and crimping, where heat welds the plastic together to seal it, or the sealing may be vacuum sealing, where the product goes into a vacuum chamber and has the air removed and product cells compressed prior to sealing.

There are several types of bag sealer to suit different sizes and types of operations and products, for example AudionMagneta Sealers or a Hulme Martin bag sealer.

The Audion Magenta range comprises of manually operated heat sealing machines for small to medium product ranges, they are proud of their safe and user-friendly range. The machines can be hand or foot operated, according to the needs of production and is suitable for sealing most plastic materials, they can be adjusted for size and sealing times, according to what is being packaged. They are suitable for a range of plastics.

Hulme Martin offer a range of hand or foot operated heat sealers of various sizes to suit different operations, including large sealing machinery. There is quite a variety to suit budget and operation, and with additional technology such as timers, trimmers to remove additional material, and seal width and size adjusters.

Whatever your needs regarding sealing, there is a Bag Sealing Machine for your workforce and production, and the investment is worth the saving in labour and time, and brings increased efficiency and competent finish to plastic packed products.